NAS Stainless to Used in New York’s “Freedom Tower”

North American Stainless steel will be used in the “cable wall” located in the lobby of “One World Trade Center” also known as the “Freedom Tower” in New York City.

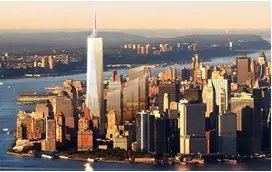

The signature building currently being constructed will become the centerpiece of the World Trade Center construction project when it opens to the public in 2013. With a total height of 1776 feet, the “Freedom Tower” will rise from a square base and taper into eight tall isosceles triangles forming a perfect octagon at its center which will be topped by an observation deck and a square glass parapet rotated 45 degrees from the base.

Freedom Tower will feature 60 foot high entrances on all four sides making it open and accessible to the community and street life that will surround it. Upon entering the building’s lobby, visitors will be able to appreciate the modern design with extensive use of glass in order to enhance the natural light as well as stainless steel for a clean and modern look.

The architectural plans for the lobby, drawn by renowned architects “Skidemore, Owings & Merrill” call for the use of T316L premium grade stainless steel for the plates that will make up the cable wall. The construction of this critical area of the lobby has been awarded to “American Architectural Inc”, experts in ornamental metal and glass design and construction.

The stainless steel plates had to be of a uniformly perfect quality with a polished finish. As a result, “American Architectural Inc” turned to “TAD Metals, Division of O’Neal Steel Industrial Metals Group” and “North American Stainless, (NAS)” to supply the plates. Two hundred and thirty tones of 2″ plates were produced at the Ghent, Kentucky NAS plant.

The stainless steel type T316 supplied by NAS has a high corrosion resistance resulting from its content of Chrome, Nickel and Molybdenum and it is used in a number of architectural and engineering applications.

Workers at NAS were overjoyed when they found out about the project, with comments such as “it’s great that a project with such National significance should use American made stainless steel”.